Aluminum Formwork Systems > Aluminum Formwork & Accessories

Aluminum Formwork & Accessories

Aluminum Formwork is a modern construction solution designed to streamline and accelerate the process of concrete forming. Built using high-strength, lightweight aluminum alloys, this formwork system ensures superior accuracy, rapid assembly, and consistent surface quality. It is ideal for repetitive construction projects like residential towers, mass housing, and commercial buildings.

Unlike traditional systems, aluminum formwork allows for monolithic casting of walls, slabs, beams, and staircases – all in a single pour. With high reusability, reduced labor requirements, and minimal maintenance, this system is quickly becoming the go-to choice for developers and contractors across the globe.

Components & Accessories

Our Aluminum Formwork System consists of robust and modular components, designed to interlock and align effortlessly:

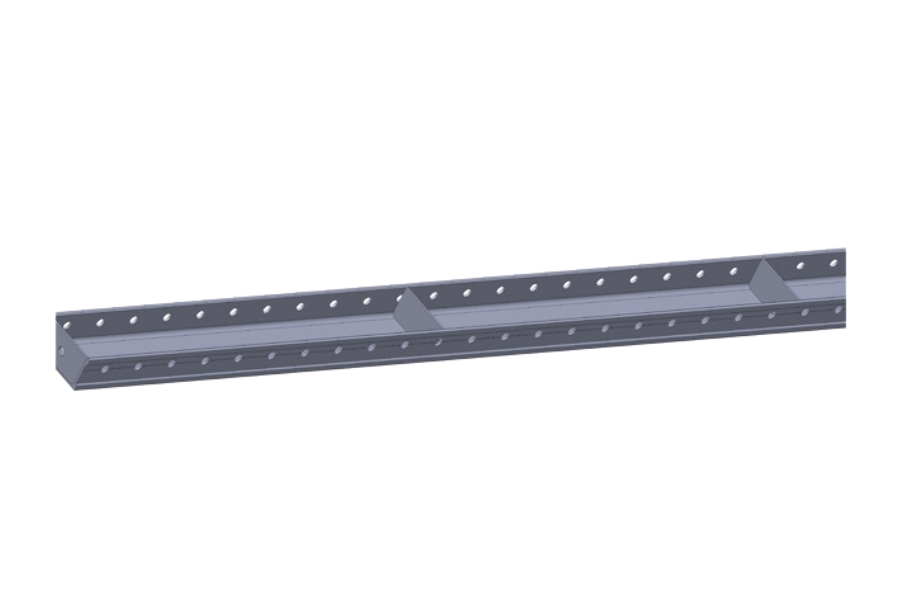

Wall Panels

For vertical surfaces such as wals and lift cores.

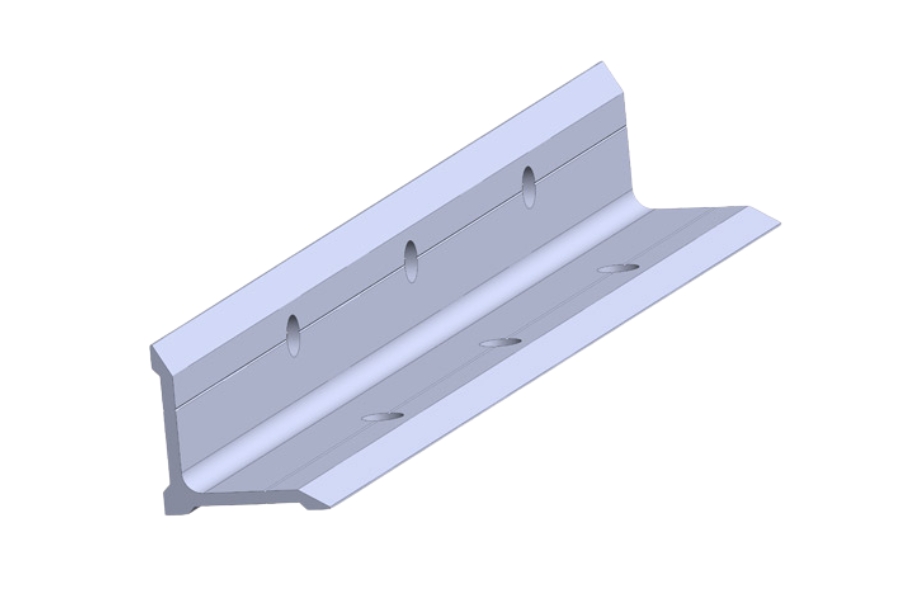

Slab Panels

Designed for casting horizontal surfaces like slabs and soffits.

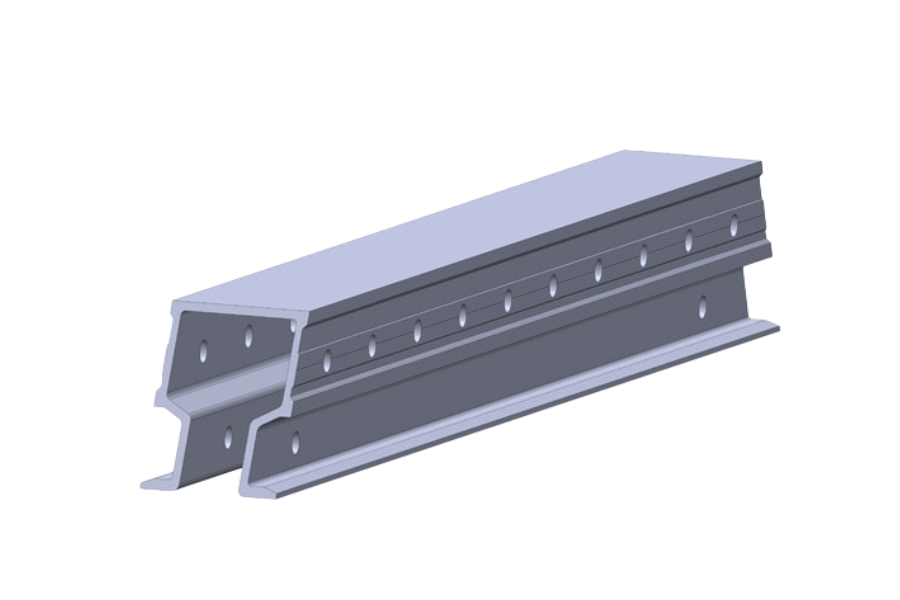

Beam Panels

For forming beams seamlessly with slabs.

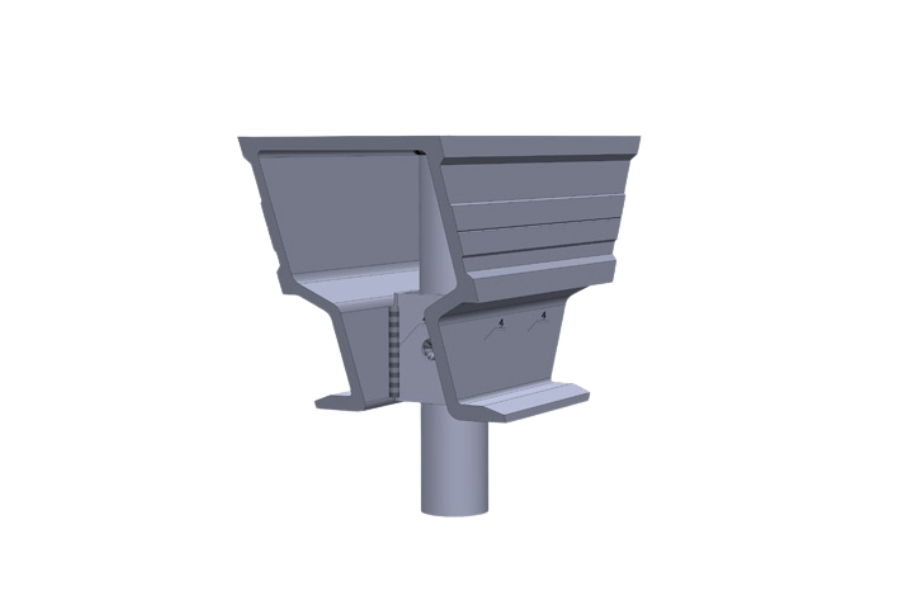

Deck Props

Adjustable props for supporting slabs and beams.

Pins & Wedges

To lock panels tightly and ensure leak-proof joints.

Corner & Junction Panels

Special elements to handle corners and junction points.

Starter/Stopper Panels

Used to control the start or stop of casting.

and more...

Advantage of Aluminium Formwork

Rapid Floor-to-Floor Casting

Achieve minimal cycle time with fast and efficient concrete pours

Structural Cost Savings

Reduce overall construction costs by up to 15% compared to traditional formwork systems.

Maximized Floor Area

Gain over 8% more usable floor space due to thinner walls and precision design.

Superior Structural Stability

Monolithic casting ensures long-term durability, rigidity, and earthquake resistance.

Reduced Labour Dependency

Simplified assembly and dismantling minimize the need for skilled labor.

Uniform Finish Across All Units

Consistent formwork design guarantees identical finishing throughout the building.

Easy Assembly & Reuse

Lightweight and modular components make on-site handling quick and hassle-free.

High Reusability

Each set can be reused up to 200 times, ensuring long-term return on investment.

Why Choose Our Aluminum Formwork?

Precision-Driven Design Approach

Every drawing goes through multiple-tier checks to ensure engineering accuracy and structural reliability.

Trusted Sourcing & Vendor Evaluation

Strict vendor screening processes and raw material traceability ensure consistent quality from the ground up.

Superior Grade Aluminum Materials

We use only 6061 T6 aluminum for extrusions and 5052 H32 grade for sheets — offering unmatched durability and strength.

Certified Welding & Materials Integrity

All welding consumables are 5356 (1.2mm) grade and conform to ISO 15607:2003 standards for secure joints and long life.

Advanced Manufacturing Processes

State-of-the-art automated machines ensure uniformity, tight tolerances, and faster turnaround.

Stringent Quality Checks

Our zero-tolerance policy includes multi-point inspections and random sampling to eliminate defects at every stage.

Smarter Builds Start With Adaptec Aluminum Formwork

Talk to our product expert or request a custom quote today.